Introduction

In the ever-evolving landscape of manufacturing and design, technology continues to push boundaries and redefine what is possible. One such groundbreaking innovation that has transformed industries worldwide is the digital cutting machine. Combining precision, speed, and versatility, these machines have revolutionized the way materials are cut, shaped, and designed. In this blog, we will explore the fascinating world of digital cutting machines, delving into their functionalities, applications, and the impact they have on various sectors.

**1. Understanding Digital Cutting Machines: A Technological Marvel

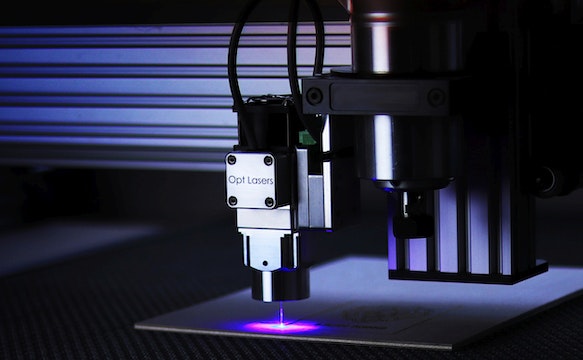

Digital cutting machines, often equipped with computer numerical control (CNC) systems, are engineered to cut a wide range of materials with unparalleled accuracy. These machines use advanced software to interpret design specifications and execute intricate cutting patterns, enabling precise customization and mass production.

**2. Applications Across Industries: Where Precision Meets Creativity

**2.1. Textile Industry: Enhancing Fashion and Apparel

Digital cutting machines have transformed the textile industry by enabling intricate fabric cuts, appliqués, and pattern making. Fashion designers and manufacturers benefit from the precision and speed these machines offer, leading to quicker production cycles and a surge in creative possibilities.

**2.2. Automotive Sector: Optimizing Efficiency and Safety

In the automotive sector, digital cutting machines are utilized for cutting various materials like leather, foam, and composite materials. These machines ensure consistency in parts, enhancing the overall safety and performance of vehicles. Additionally, they facilitate rapid prototyping, allowing for faster innovation and product development.

**2.3. Packaging Industry: Tailoring Solutions for Brands

Digital cutting machines play a pivotal role in the packaging industry, enabling the production of custom-designed packaging solutions. Brands can create unique shapes, intricate designs, and personalized packaging that align with their branding strategies. This level of customization enhances product visibility and consumer engagement.

**3. Advantages of Digital Cutting Machines: Precision, Efficiency, and Sustainability

**3.1. Precision and Customization

One of the primary advantages of digital cutting machines is their ability to achieve intricate cuts with exceptional precision. This precision is invaluable in industries where customized, complex designs are the norm.

**3.2. Operational Efficiency and Cost-Effectiveness

Digital cutting machines significantly reduce production time and labor costs. With automation at the helm, repetitive tasks are streamlined, leading to increased efficiency. Additionally, the ability to store and reproduce designs digitally reduces material wastage, making these machines environmentally friendly and cost-effective.

**3.3. Sustainability and Waste Reduction

By optimizing material usage and minimizing wastage, digital cutting machines contribute to sustainability efforts. Industries adopting these machines can reduce their environmental footprint, making them an attractive choice for eco-conscious businesses.

**4. Challenges and Future Developments: What Lies Ahead

While digital cutting machines offer a myriad of benefits, challenges such as initial setup costs and the need for skilled operators must be addressed. Additionally, ongoing advancements in artificial intelligence and machine learning are expected to enhance these machines further, enabling them to handle even more complex tasks and materials.